Wenzhou Kangtian Auto Parts Co., Ltd.

—— Craftsmanship in manufacturing, securing infinite possibilities!

Our company specializes in manufacturing high-quality fasteners, mainly used for automotive parts and electrical equipment. Equipped with advanced production and testing facilities, as well as a scientific quality management system, we supply renowned domestic enterprises. Welcome friends from all walks of life to contact us for business negotiations and cooperation.。

Company Overview

"Deepen efforts with perseverance, forge a model in the industry."

Located in Ruian, Zhejiang—known as "China's Automotive and Motorcycle Parts Capital"—our company was founded in 2012 with a 9,000㎡ standard production workshop. Specializing in high-strength fasteners for automotive, motorcycle, and mechanical applications, we leverage a 50+ professional team (30% technical and quality personnel) and advanced equipment, including multi-station cold heading machines, precision thread rolling machines, lathes, grinders, stamping equipment, and heat treatment lines. Our in-house inspection lab ensures strict quality control over product performance. Upholding the principles of "customer first, credibility-based, quality priority, and continuous improvement," we aim to create shared value with clients through close collaboration.

Product and Service

"Full-category coverage to meet diverse needs."

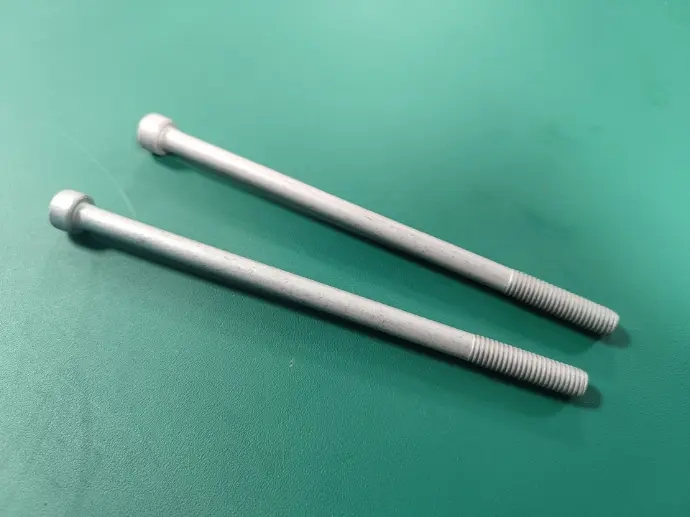

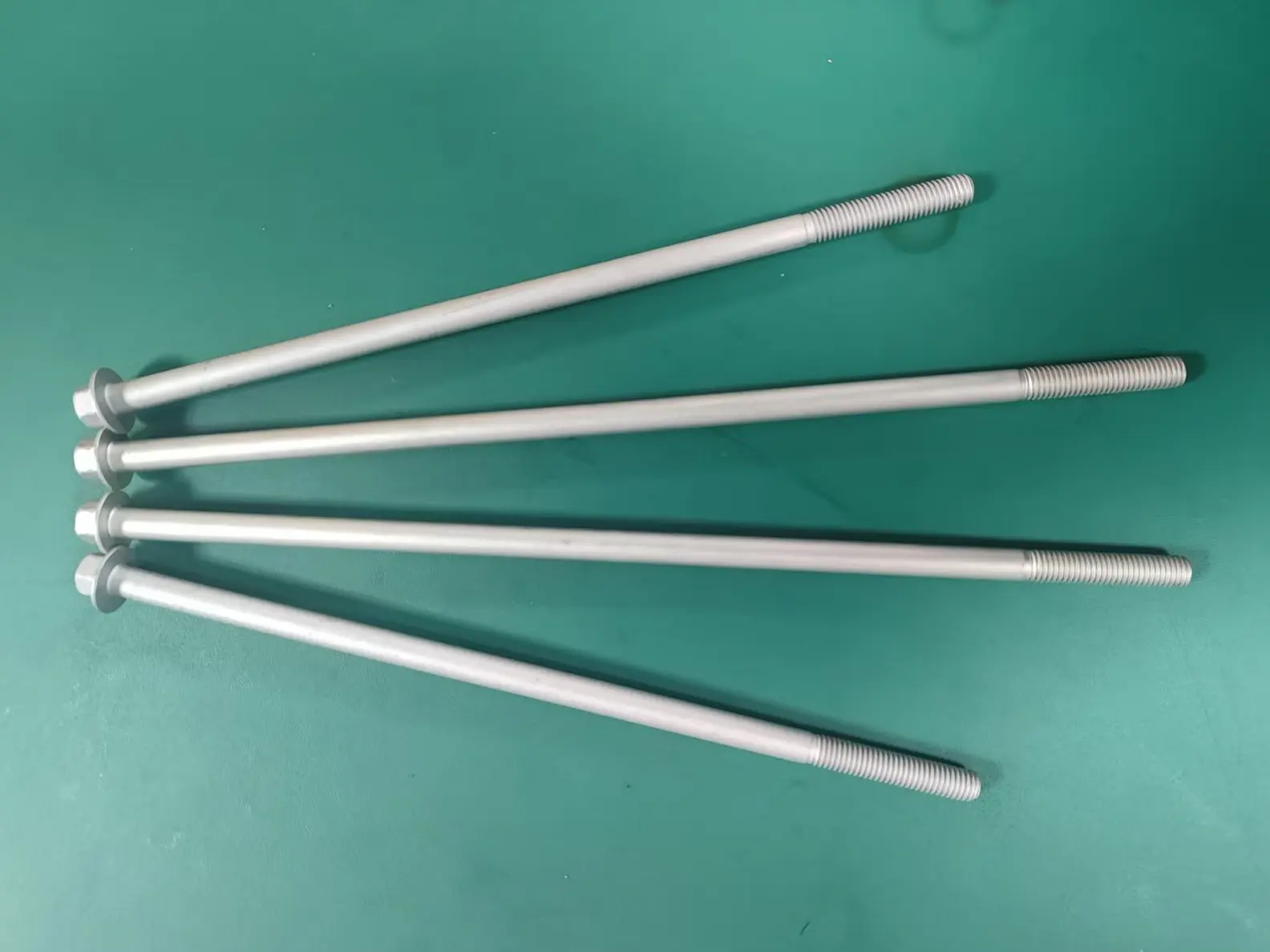

- Bolts: High-strength hex flange bolts, adhesive-coated bolts, long bolts, etc.

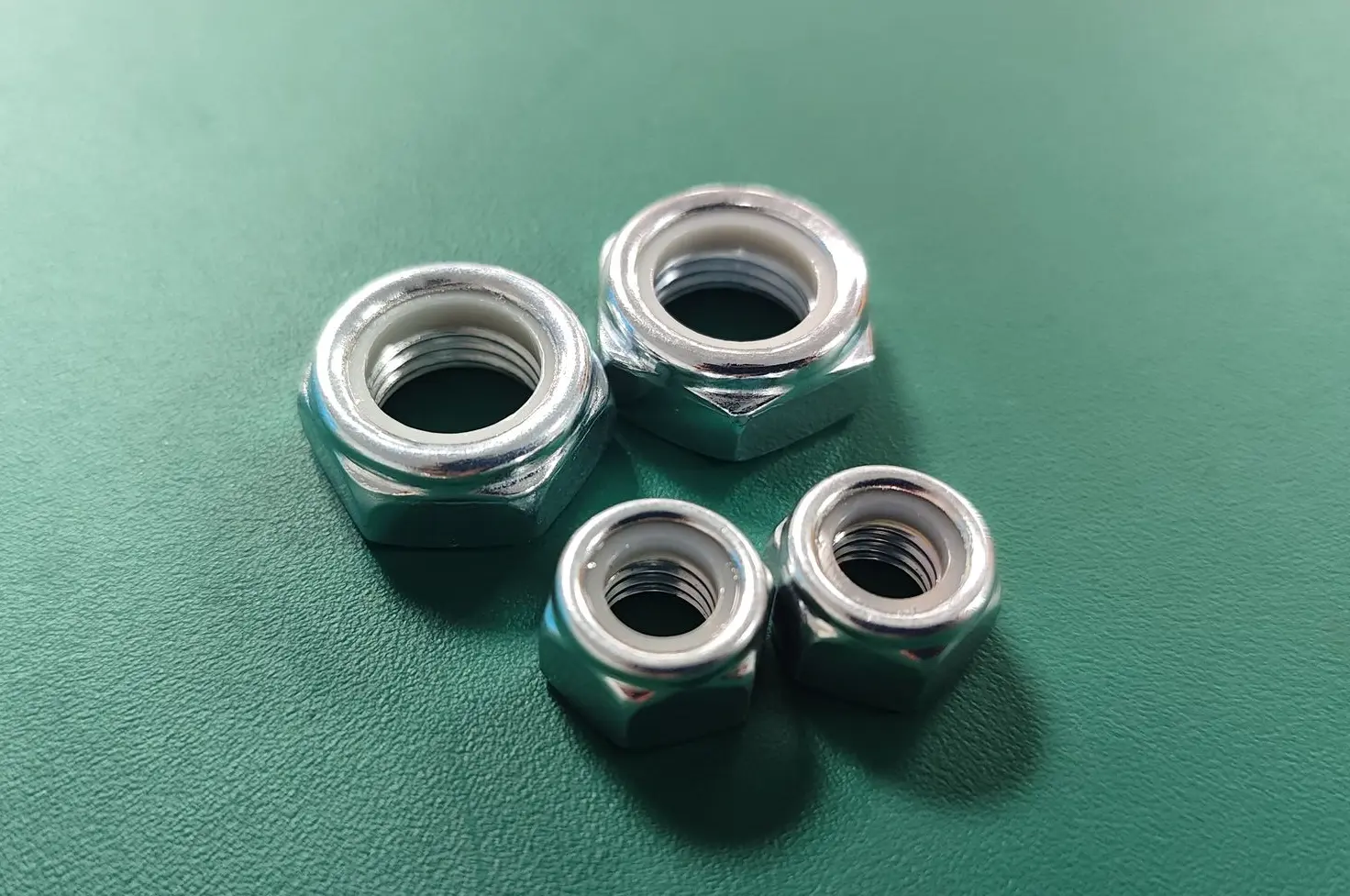

- Nuts: Hex nuts, flange nuts, lock nuts, self-locking nuts, etc.

- Screws: Pan head cross recess screws, pan head torx screws, self-tapping screws, etc.

- Washers: Flat washers, spring washers, lock washers, etc.

- Others: Flat keys, rivets, assemblies, non-standard custom parts, etc.

Product Advantages

- Premium Materials Selection :Strictly select high-quality steel to ensure material performance from the source.

- High-precision Manufacturing :Adopt advanced processing and inspection procedures to strictly meet customer requirements for precision and performance.

- Complete Specifications :Cover full-series specifications and models, while supporting personalized non-standard customization.

- Timely Delivery

:Enable rapid R&D, testing, and production, with cooperative logistics ensuring on-time delivery.

Quality Control

"Strict control throughout the process, excellent quality."

- Certified to IATF16949:2016, we implement a comprehensive end-to-end quality management system with strict testing with advanced equipment covering raw material procurement, production, to final inspection.

- Equipment includes direct-reading spectrometers, friction coefficient analyzers, roughness profilers, metallographic analyzers, cleanliness analysis systems, microcomputer servo tensile testing machines, Rockwell/Vickers hardness testers, and salt spray test chambers.

- Every batch undergoes rigorous inspection—most products are 100% dimensionally screened via computer vision systems to meet customer requirements.

- We adhere strictly to client quality standards, pursue continuous improvement toward zero defects, and ensure stable, reliable product quality.